Jun . 11, 2024 16:52 Back to list

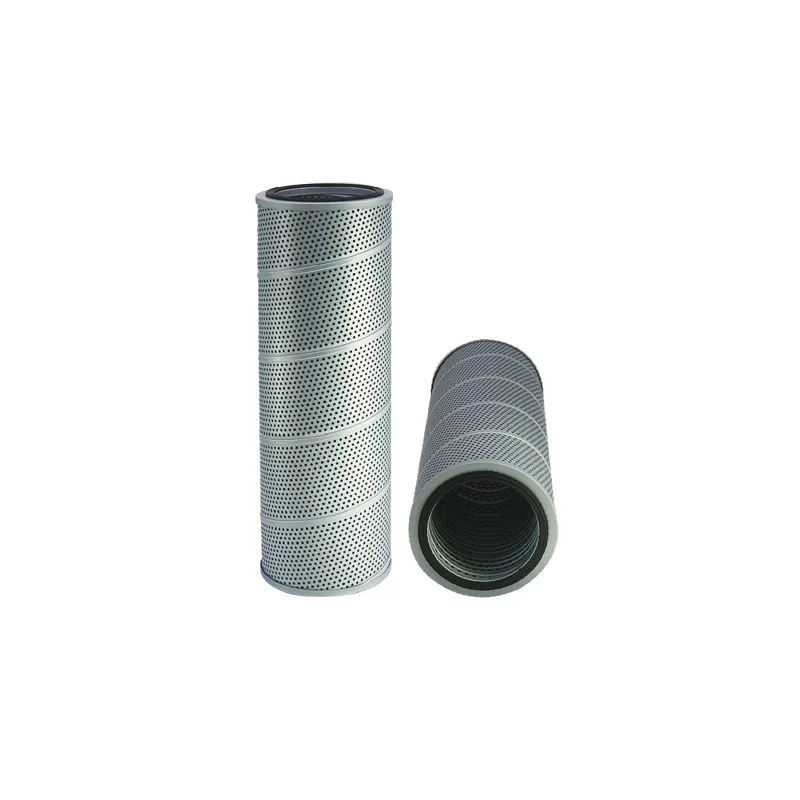

Diagnosis of 6 Major Problems with Excavator Filter Element!

Diagnosis of 6 Major Problems with Excavator Filter Element!

1、 Why do filter elements need to be replaced on time?

The main function of the filter element of an excavator is to filter impurities and dust. If it is not replaced on time, there will be too many impurities, and the oil cannot be filtered. The oil circuit will be blocked, leading to wear and tear of the excavator and affecting normal operation.

2、 Under what circumstances must the filter element be replaced?

- Normal replacement time

- Abnormal replacement situation:

a、 When the filter pressure gauge alarms or the pressure is abnormal, check if the filter is abnormal. If it is abnormal, it must be replaced.

b、 If there is leakage or deformation on the surface of the filter element, it is necessary to check whether the filter element itself is abnormal. If there is any abnormality, it must be replaced.

3、 The higher the filtration accuracy of the filter element, the better?

The higher the precision of the filter element, the better its ability to absorb dirt and reduce wear. Compared to the secondary filter element, the pure parts of Shensteel have higher filtration accuracy, which can extend the service life of excavators.

4、 The filter element is cheap, can it be installed?

Many filter cartridges on the market are relatively cheap and can be installed on excavators, but the filtration accuracy often does not meet the requirements, which can cause impurities, iron filings, etc. to enter fuel, hydraulic oil, and engine systems, leading to engine overhaul.

5、 What is the impact of using inferior filter cartridges on excavators?

Impact on fuel system

The combustion characteristics of the electronic injection engine of Shensteel will produce a large amount of smoke, and if the smoke particles (carbon particles) are not filtered out in time, they will gather and produce abrasive effects, increasing the wear of engine piston rings, large and small bearings, cam surfaces and other components.

Impact on hydraulic system

The hydraulic oil system is susceptible to dust and impurities at any time. More than 70% of excavator failures are caused by excessive impurities in the hydraulic system, resulting in wear and tear of hydraulic systems such as hydraulic pumps, multi way valves, rotary motors, and walking motors.

6、 The excavator has a long service life, and there is no difference between using good and bad filter cartridges?

The longer the excavator is used, the easier it is for the engine to wear out and pull the cylinder. Therefore, older excavators need to use high-quality filter elements to ensure the normal operation of the engine.